Could thermochemical water splitting threaten electrolyzers?

NewHydrogen, the developer of ThermoLoop™, a new technology that uses water and heat rather than electricity to produce low-cost green hydrogen, has revealed the details behind its approach to water splitting.

“We believe ThermoLoop will be a game changer compared to conventional low-performance electrolyzer technology,” said NewHydrogen CEO Steve Hill. “ThermoLoop can be configured as a drop-in replacement for electrolyzers, making them obsolete. Simply put, we believe that ThermoLoop will be an electrolyzer killer.”

Mr. Hill continued: “Using heat, rather than electricity, is simply a better way to split water to make green hydrogen. Heat is cheap. It can be found everywhere, including concentrated solar, nuclear reactors, and waste heat from industrial plants, such as oil refineries and cement and steel manufacturing plants. Heat-based systems are more scalable and have the potential to be cheaper than electrolyzer systems.”

The challenge

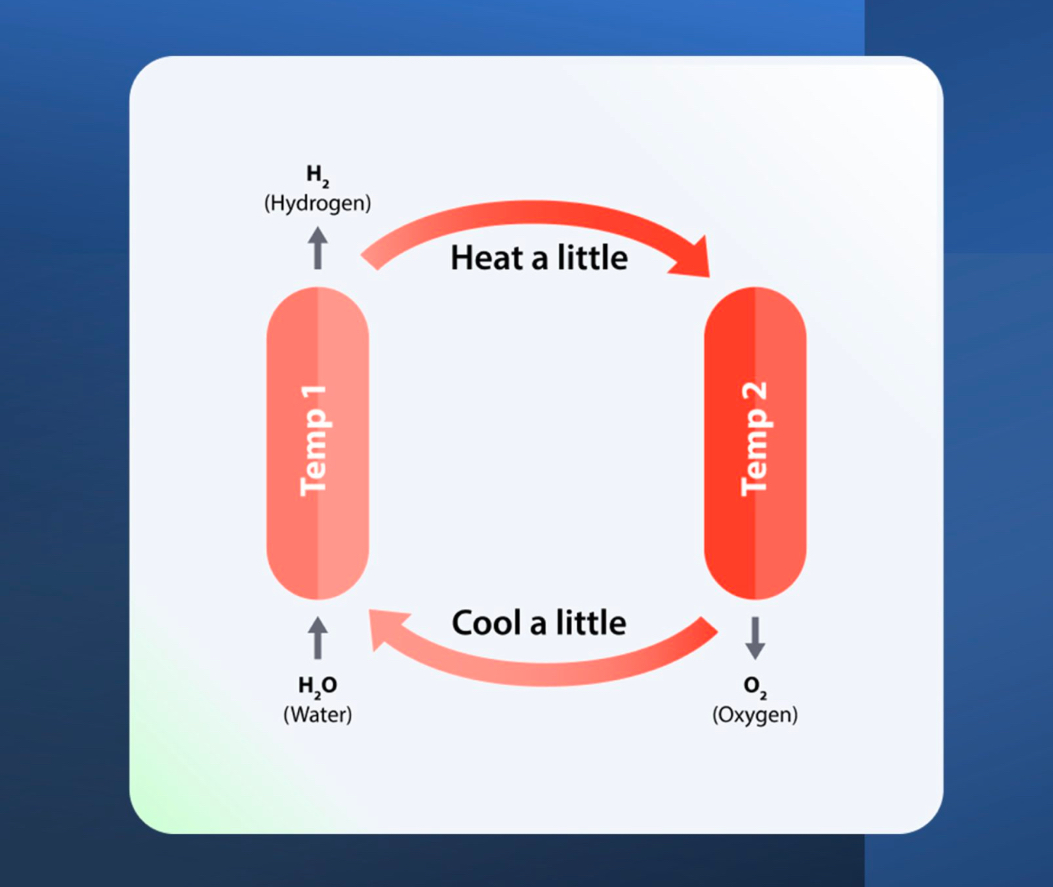

Scientists have long been researching efficient methods to use heat for water splitting. One of the main challenges in developing a heat-based system is the temperature mismatch between the different chemical reactions involved. The reaction that extracts hydrogen from water typically occurs at a lower temperature, while the reaction that extracts oxygen requires a higher temperature. During the heating and cooling phases, hydrogen production pauses, leading to energy losses and reduced efficiency.

The approach

NewHydrogen is developing a method to use heat for water splitting that enables all reactions to occur at nearly the same temperature. These reactions are known as near-isothermal reactions, and the process is referred to as thermochemical water splitting.

To achieve near-isothermal reactions, NewHydrogen is designing novel materials and chemical processes. By bringing the first reaction temperature closer to the second, system downtime is reduced. The ThermoLoop system requires only minor heating and cooling adjustments, allowing hydrogen production to continue with minimal interruptions. According to the company, this approach improves overall efficiency.

NewHydrogen is utilizing artificial intelligence and machine learning tools to explore the periodic table and systematically test combinations of different elements. The goal is to identify materials with the optimal properties needed to facilitate scalable isothermal reactions.

The technology

The California-based company has developed a series of chemical reactions that leverage the phase change properties of its novel material, transitioning between solid, liquid, and gas states before returning to solid. This phase change helps reduce the temperature difference between reactions, which, according to NewHydrogen, is a key factor in enabling near-isothermal reactions for the continuous production of hydrogen from water.

The company integrates these advancements into ThermoLoop, a thermochemical water-splitting system designed for scalability. According to NewHydrogen, this approach has the potential to ‘produce the world’s cheapest green hydrogen.’

Mr. Hill concluded: “ThermoLoop is agnostic to the sources of heat and water. If we simply couple ThermoLoop with any available source of heat and water, we can create an incredibly efficient, low-cost, clean and green hydrogen production machine – anywhere, anytime. What if heat is hard to get? No problem. Because the thermodynamics of heat systems are more efficient and scalable than electrolyzer systems, we believe we can convert electricity to heat to run ThermoLoop and still outperform electrolyzers.”