Seawater electrolysis one of 10 hydrogen projects funded to ‘accelerate net zero’

Seawater electrolysis one of 10 hydrogen projects funded to ‘accelerate net zero’

Seawater electrolysis, repurposing of offshore oil and gas assets for hydrogen production and storage, and decarbonised steel production will all be explored as part of 10 new hydrogen-focused projects.

The UK Hub for Research Challenges in Hydrogen and Alternative Liquid Fuels (UK HyRES) awarded a total of £3m to researchers working on the schemes today (17 January). Based at the University of Bath, HyRES is aimed at accelerating the net zero transition.

Professor Tim Mays, leader of the initiative, said :

We are delighted to welcome 10 new research projects to UK HyRES.

“The projects cover all our hub themes – hydrogen production, storage and end use and alternative carriers – and join the 14 core projects already underway in the hub,This gives UK HyRES a comprehensive base of top-tier research expertise to help answer the key questions around how we can use hydrogen and zero-carbon alternative liquid fuels to help reach net zero.”

An announcement said,

The projects will seek to address obstacles that currently stand in the way of greater adoption of hydrogen and low-carbon liquid fuels and seek to better understand ways to efficiently produce and use, and safely store and transport them,

The schemes include:

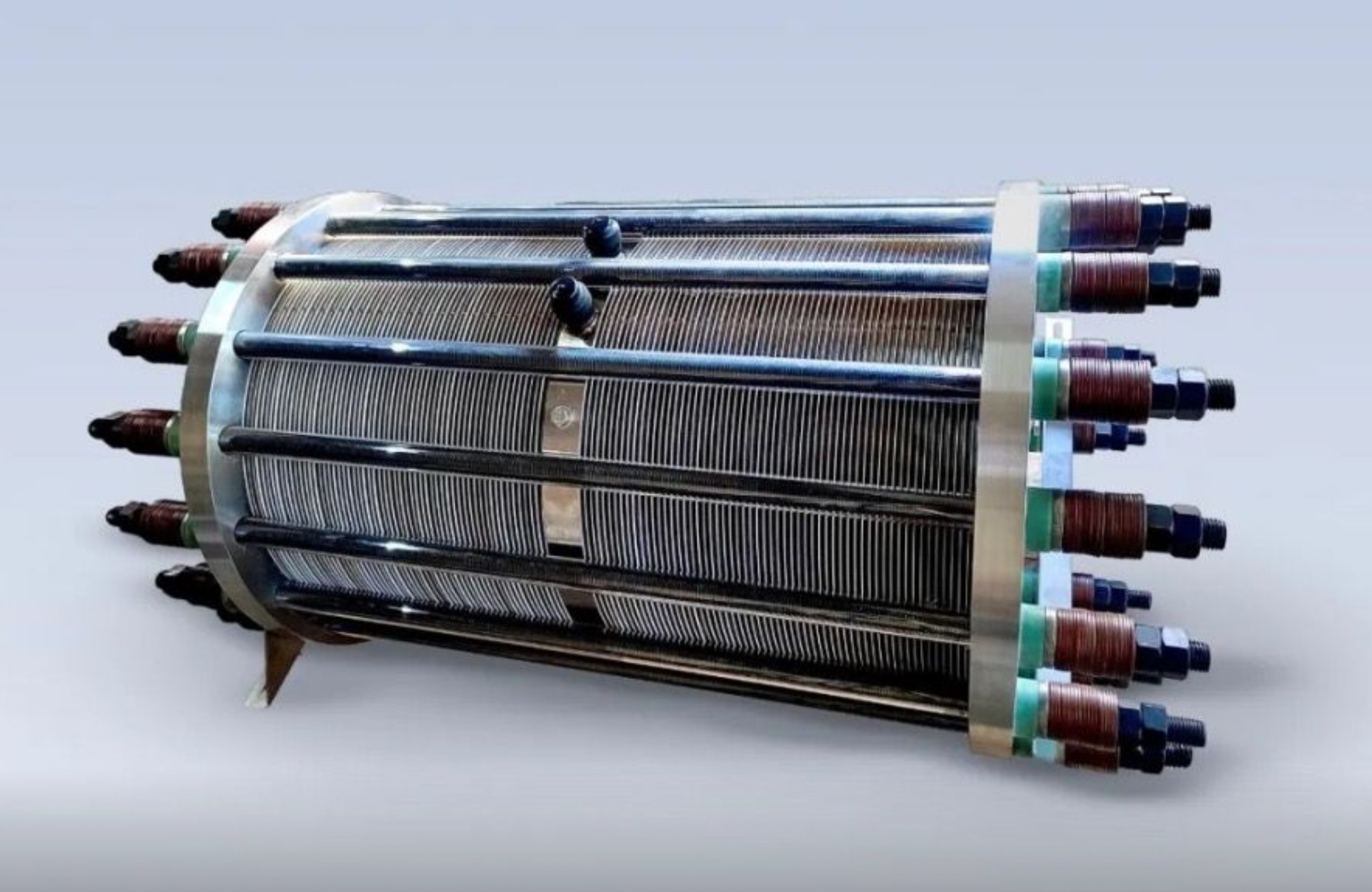

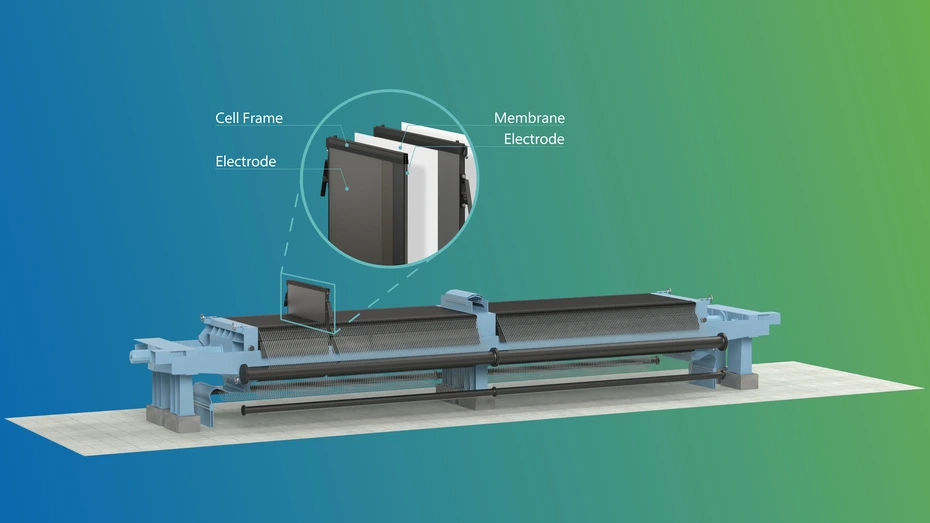

Decoupled electrolysis of seawater

Led by Professor Mark Symes at the University of Glasgow, this project will research the potential to create an electrolyser that can produce hydrogen directly from seawater, by using decoupled electrolysis – forming the oxygen and hydrogen products at different times, at different rates and in different locations.

The announcement said,

Producing hydrogen directly from seawater would be a major breakthrough, particularly where freshwater supplies are limited, such as in offshore or desert locations,

Repurposing the economy future of the North Sea

This project, led by Dr Alfonso Martinez-Felipe at the University of Aberdeen, aims to optimise key mechanical properties of materials used for hydrogen storage and transport, enhance the safety of long-distance hydrogen transmission networks, and determine the feasibility of repurposing offshore assets in the North Sea for hydrogen production, generation and storage.

Multi-purpose exploration of ammonia reduction of iron oxides to enable green steel and high purity

Professor Aidong Yang at the University of Oxford will lead this project, exploring ammonia’s use as a hydrogen carrier, and ammonia and hydrogen direct reduction in steel production.

Source: Hydrogencentral