HYDGEN and Tridiagonal Solutions Pvt. Ltd. Sign Strategic MoU for Small-Scale Electrolyzer Collaboration

MANGALORE, KARNATAKA, INDIA, May 6, 2025 /EINPresswire.com/ -- HYDROGEN INNOVATION PVT. LTD. (HYDGEN), a leader in the development of advanced Anion Exchange Membrane (AEM) electrolyzers, and Tridiagonal Solutions Pvt. Ltd. (TSPL), a renowned entity specializing in small-scale electrolyzer systems, are pleased to announce the signing of a Memorandum of Understanding (MoU) to collaborate on the development, testing, and deployment of small-scale electrolyzer systems for various industrial applications.

This collaboration will enable both companies to jointly develop, test, and deploy small-scale electrolyzer systems that will accelerate the transition to sustainable energy in key sectors such as energy storage, mobility, and industrial hydrogen use. By combining HYDGEN’s cutting-edge electrolyzer technology with TSPL’s expertise in system testing and deployment, the partnership will play a pivotal role in proving the commercial viability of small-scale hydrogen production systems.

The key values of this new partnership are:

- Accelerating decarbonization: The partnership will focus on demonstrating how small-scale electrolyzers can help decarbonize industries that rely on hydrogen as a feedstock, including energy storage, transportation, and manufacturing. With both companies committed to providing practical, real-world solutions, the collaboration will directly contribute to reducing carbon emissions across multiple sectors.

- Innovation in hydrogen technologies: HYDGEN’s advanced AEM electrolyzer technology is at the forefront of green hydrogen production, offering a more sustainable and cost-effective alternative to traditional hydrogen production methods. This collaboration will facilitate the real-world testing and refinement of these technologies, ensuring they are ready for large-scale deployment.

- Pilot projects and market validation: Through joint pilot projects, the partnership will validate the performance and efficiency of small-scale electrolyzer systems, allowing both companies to gather valuable data and refine their offerings. This will provide critical insights for potential customers in sectors such as mobility, energy, and industrial hydrogen production.

- Infrastructure and market access: TSPL’s strong infrastructure, extensive testing facilities, and market reach will provide the ideal platform for scaling up these technologies. With access to a wide array of industries, TSPL will support the deployment and performance testing of electrolyzer systems, helping to establish a strong market presence for the new technology.

"We are excited to partner with TSPL to accelerate the adoption of small-scale electrolyzer technology, which is a critical step toward achieving sustainable energy solutions and supporting the decarbonization of key industries," said Dr. Manippady Krishna Kumar, COO of HYDGEN. "This collaboration aligns with our vision to lead the way in clean hydrogen production and empower industries to transition to green energy."

About HYDGEN

HYDGEN is a leading developer of anion exchange membrane (AEM) electrolyzers, designed to enable affordable, decentralized green hydrogen production. Their advanced systems offer unmatched efficiency and operational flexibility, a compact footprint, and reduced supply chain risk by avoiding the use of rare earth metals. By eliminating reliance on centralized supply chains, HYDGEN’s technology makes clean hydrogen accessible and scalable for industries of all sizes.

HYDGEN and Tridiagonal Solutions Pvt. Ltd. Sign Strategic MoU for Small-Scale Electrolyzer Collaboration

Signing of MoU at HYDGEN Innovation Day We are excited to partner with TSPL to accelerate the adoption of small-scale electrolyzer technology, which is a critical step toward supporting the decarbonization of key industries”— Dr. Manippady Krishna Kuma

fox59.com

'New Energy' 카테고리의 다른 글

| SunHydrogen Contracts The Process Group for Front-End Engineering Design of 25 M² Renewable Hydrogen Pilot Plant (0) | 2025.05.08 |

|---|---|

| Sungrow Hydrogen Launches the 300Nm³/h PEM Water Electrolyzer (0) | 2025.05.08 |

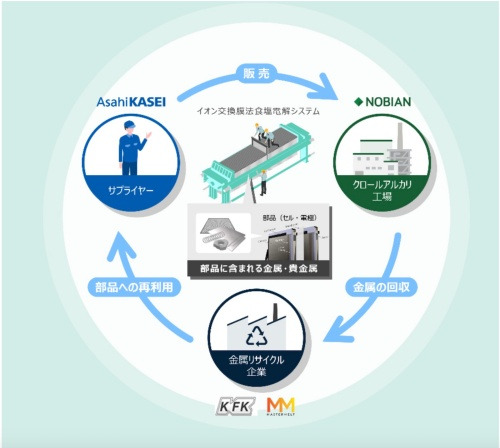

| 食塩電解セルから希少金属を回収・再生、旭化成ら日欧4社が実証 (0) | 2025.05.07 |

| キリン千歳工場、ボイラーに水素活用、太陽光で水電解 (0) | 2025.04.30 |

| IMI 4MW PEM Electrolyser Boosts Green Hydrogen Production at API SARPOM Refinery (0) | 2025.04.25 |