ミストCVD法による新しいグリーン水素生成技術の実証成功

持続可能な社会に向けて水電解の低コスト化に期待

立命館大学総合科学技術研究機構(滋賀県草津市)の金子健太郎教授(半導体応用研究センター〈RISA〉センター長、立命館先進研究アカデミー〈RARA〉フェロー)、同大学大学院理工学研究科の荒木努教授、同研究科博士前期課程2回生の服部太政さんらの研究グループは、岩崎電気株式会社(東京都中央区、代表取締役社長:伊藤義剛)、アイテック株式会社(福井県鯖江市、代表取締役社長:黒田優)と共同で、安価な半導体成膜方法であるミストCVD法※1を用いて、水電解セパレータ※2に有効な低抵抗かつ高耐食性を有する金属酸化物膜(酸化スズ〈SnO2〉、酸化インジウム〈In2O₃〉)の作製に成功し、水電解で使用されるセパレータに対し、ミストCVDで成膜した金属酸化膜が有用性のあることを世界で初めて示しました。

本研究成果は、2024年9月の第85回応用物理学会秋季学術講演会、2024年10月の第43回電子材料シンポジウム(EMS)、2024年12月には材料研究に関する世界有数の国際科学会議2024 MRS Fall Meeting & Exhibit(米国ボストン)などにて報告いたしました。

また、論文情報の内容は、2023年11月に行われた第3回半導体エレクトロニクス部門委員会第2回研究会にて、学生優秀講演賞を受賞しました。

研究の背景

2050年のカーボンニュートラル実現と水素社会に向けて、日本政府は2023年6月に水素を主なエネルギー源とする国家戦略「水素基本戦略」の改訂や、2024年5月に水素の社会実装を強力に推進していくための法律「水素社会推進法」の成立など実現に向けた政策や目標を掲げています。

水素は直接的に電力分野での貢献だけでなく、太陽光発電などの再生可能エネルギーの余剰電力を水素に変換して貯蔵・利用することで、再生可能エネルギーのゼロエミッション電源として活用することができます。

そして岩崎電気株式会社では、再生可能エネルギーを利用した地域自立分散型エネルギーシステムや、直流機器デバイス(太陽電池、蓄電池、水電解、燃料電池、照明など)を直流でつなぐ直流給電システムなど、地域エネルギーの効率的利用に向けた開発に取り組んでいます。

またアイテック株式会社では、新しい水素社会実現に向けて水電解用金属セパレータのミストCVD法による高耐食性膜の開発に取り組んでいます。

図1. 給電システムの例

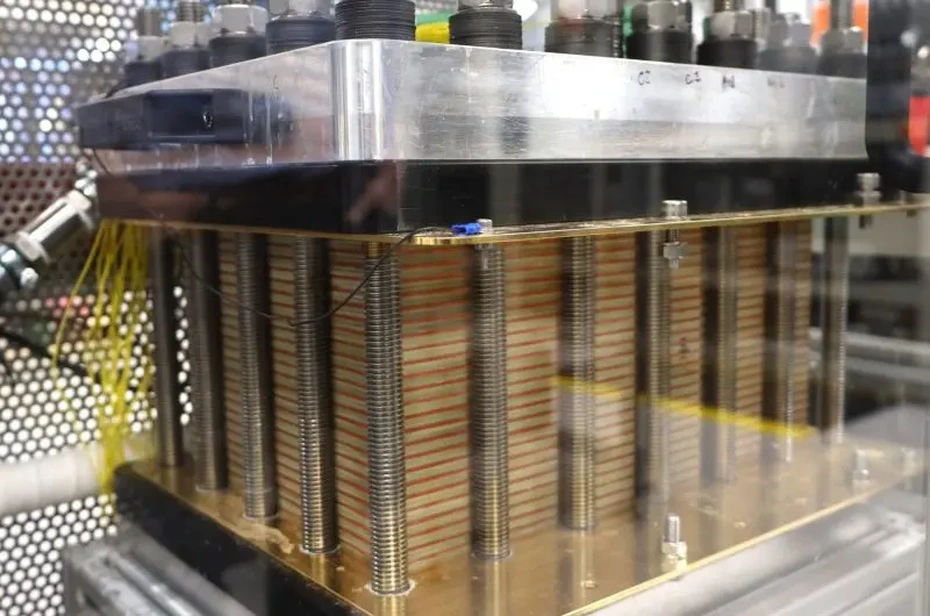

水を電気分解して水素を生成する水電解装置(図2)は、再生可能エネルギーのゼロエミッション電源と組合せ、これからの持続可能な社会実現に向けて活用が期待されています。

その中でも固体高分子(PEM)型水電解※3は、高いエネルギー効率や水素生成速度が速いこと、再生可能エネルギーのような変動電圧への対応が可能であること、取り出せる水素ガスの純度が高いこと、高電流密度での運転が可能で小型化できる、などの特長があり注目されています。

図2. 水電解セルの模式図

固体高分子(PEM)型水電解は、燃料電池(0.7V)以上に高い電位(>2V vs. 水素電極:RHE)にさらされることなどでの酸性環境下の電気化学反応となるため、水電解で使用する水電解セパレータは高性能な耐腐食性と導電性が求められ、現在はチタン(Ti)セパレータ上にプラチナ(Pt)をコーティングする手法がとられていますが、高コストの貴金属類を使用するため、作製コストが課題となっていました。

そこで本共同研究グループは、この酸性環境下で安定して水の電気分解を低コストで実現するための研究開発として、これまで研究を行っていた低コスト成膜法であるミストCVD法を用いて、燃料電池セパレータへのSnO2やIn2O₃のコーティング技術※論文情報を水電解用セパレータなどへの技術応用の可能性を示すために実験を試みました。

研究成果

本研究では、ミストCVD法を用いてSnO2とIn2O₃をTi基板にそれぞれ成膜しました。

評価方法としては、固体高分子(PEM)型水電解の酸性環境を再現する硫酸水溶液中で電極性能の検証を行いました。

接触抵抗は四端子法を用いて試料の垂直方向成分の抵抗値を測定し、耐食試験は内部環境を模した硫酸水溶液(H2SO₄, pH3)中で定電位分極試験を行いました。

また電位は2.0V (vs. RHE)、試験時間は72時間としました。

実験結果として、Ti基板上に成膜した低抵抗SnO2とITO(Snを添加したIn2O₃)※4は図3に示すように7.6mΩcm²、6.4mΩcm²をそれぞれ達成いたしました。

これは、金やプラチナをコーティングした際の接触抵抗値(1 - 5mΩcm²)に匹敵する値であり、セパレータの低コスト化、ひいては、水電解の低コスト化への有用性を示すことができました。

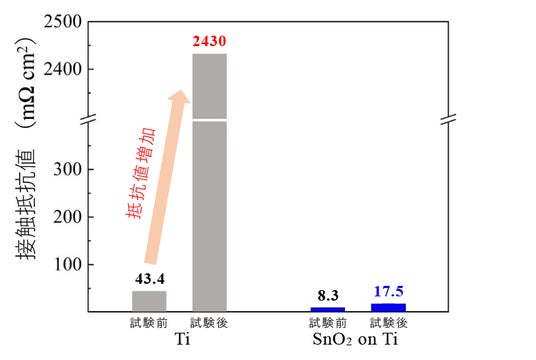

また、図4に示すように、水電解の動作環境を模した硫酸水溶中に72時間2.0V(vs. RHE)定電位分極した後のTi基板、Ti基板上に作製したSnO2(SnO2 on Ti)に対し、試験前後における接触抵抗値を測定したところ、SnO2 on Tiでは、試験後の接触抵抗値が急激に上昇することがないことが確認されました。

図3. Ti基板にミストCVD法で成膜した酸化物の接触抵抗値

図4. Ti基板上にミストCVD法で成膜した酸化物の分極試験前後の接触抵抗値

表1. 分極試験後のICP-AESによる溶出金属の定量分析結果

次に、定電位分極試験においても表1に示すように誘導結合プラズマ発光分光(ICP-AES)分析の結果、溶液中にSnやTi成分が溶出することなく良好な耐食性を示すことが確認されました。

以上の結果より、ミストCVD法による金属酸化膜が水電解セパレータ応用に十分な特性を得ることができました。

今後の展開

今回開発したミストCVD法を用いたSnO2、In2O₃の金属酸化膜は水電解での構成部品材料の低抵抗化と高耐食性を示せたことから、ミストCVDによるコーティング技術は、希少金属や貴金属類を使用せずに低コストで高効率な水の電気分解によるグリーン水素製造が可能となり、再生可能エネルギーを電源とした水電解技術の普及に大きく貢献するものと期待されます。

また本研究成果は特許出願中であり、今後は今回の成果を基に更なる特性改善に取り組み、より安価で高品質な水電解の実現に向けて研究開発を進めてまいります。

論文情報

論文名:燃料電池セパレータに被覆する導電性・耐食性ITO薄膜の作製

著者:Taisei HATTORI, Takashi TANAKA, Eiji KIKUCHI, Tomoki OTSUKA, Tsutomu ARAKI, and Kentaro KANEKO

発表雑誌:材料 (Journal of Society of Materials Science, Japan)

掲載日:2024年4月15日

DOI:https://doi.org/10.2472/jsms.73.356

URL:https://www.jstage.jst.go.jp/article/jsms/73/4/73_356/_article/-char/ja

用語説明

※1 ミストCVD法:

化学気相成長(Chemical Vapor Deposition, CVD)法の一種であり、酸化物半導体の合成などに用いられている薄膜成長手法。

成膜材料は水や有機溶媒に原料を溶かす方法のため成膜プロセスでのドーピングや混晶の作製が簡便であり、また常圧成膜が可能のため真空装置を必要としないので装置が簡便で安価である特長がある。

※2 セパレータ:

燃料となる水素ガスや酸素ガスを送り込む、生成された水を排出する流路を形成する板状の部品。

導電性と耐食性が求められる。

※3 固体高分子(PEM)型水電解:

固体高分子(PEM)型水電解は、固体高分子膜(PEM)を用いて水を電気分解する水素製造方法。

PEMはPolymer Electrolyte Membraneの略。

水電解プロセスでは、電解装置が電気と水を気体の水素と酸素に変換します。

固体高分子膜(PEM)は水素イオン(プロトン)を輸送する能力を持ち、電気分解による水素と酸素の分離や電極の電気的絶縁を確保する。

PEMはProton Exchange Membrane(プロトン交換膜)とも呼ばれる。

※4 ITO(Snを添加した酸化インジウム:In2O₃):

導電性が高いワイドバンドギャップ半導体として、ディスプレイ用途の透明導電膜として有名な金属酸化物である。

燃料電池セパレータに求められる導電性と耐腐食性を兼ね備える材料としても有用である事が論文情報の論文により示された。

関連ニュースリリース

当リリース「ミストCVD法による新しいグリーン水素生成技術の実証成功~持続可能な社会に向けて水電解の低コスト化に期待~」は立命館大学、アイテック株式会社からも本日ニュースリリースしています。

参考

立命館大学 総合科学技術研究機構 金子健太郎教授

立命館大学半導体応用研究センター長、立命館先進研究アカデミー(RARA)フェロー。

2014年京都大学 工学研究科 助教、2018年同講師を経て、2022年7月より現職。

酸化物を用いたさまざまな機能性材料の開拓・合成を専門とし、水素生成、燃料電池、メタマテリアル、真空紫外発光固体素子、パワー半導体などへの応用研究で各企業と共同研究を行っている。

アイテック株式会社

眼鏡フレーム、スポーツ用品、環境分野製品、その他多様な工業製品などに対する金属めっき、装飾用・機能性各種めっき及びその他特殊表面処理加工などの表面処理事業と、眼鏡フレームの企画・販売、ダイヤモンドワイヤの製造・販売を手掛ける。

https://eyetec.co.jp/

岩崎電気株式会社

LEDランプ、ハロゲン電球、紫外線殺菌ランプなどの光源と、道路用照明、屋外施設用照明、屋内施設用照明などの照明機器。

光・環境機器として紫外線殺菌、赤外線加熱、電子線照射、促進耐候性試験装置などの製造販売。

ミストCVD法による新しいグリーン水素生成技術の実証成功 - PR TIMES|RBB TODAY

ミストCVD法による新しいグリーン水素生成技術の実証成功 - PR TIMES|RBB TODAY

持続可能な社会に向けて水電解の低コスト化に期待立命館大学総合科学技術研究機構(滋賀県草津市)の金子健太郎教授(半導体応用研究センター〈RISA〉センター長、立命館先進研究アカ…

www.rbbtoday.com