GKN Powder Metallurgy Announces Launch of New High-Performance PTL for the Cost-Efficient Production of Green Hydrogen

GKN Powder Metallurgy, a global leader in powder metallurgy and innovative, sustainable solutions across automotive and industrial applications, has developed a new generation of Porous Transport Layers (PTL) for Proton Exchange Membrane (PEM) electrolysis. The solution is designed to revolutionize hydrogen production by increasing efficiency while reducing overall environmental impact.

Driven by a commitment to fostering a green and sustainable future, GKN Powder Metallurgy’s high-performance, high-porous, and high-purity PTL (HP-PTL) provides an advanced solution that addresses both the technological and environmental challenges faced by the hydrogen industry. This solution is the result of 10 years of dedicated research, combined with decades of powder metallurgy innovation.

By significantly reducing the required amount of catalyst materials, such as iridium, GKN’s HP-PTL lowers stack costs, increasing the affordability of advanced PEM electrolyzers compared to established solutions.

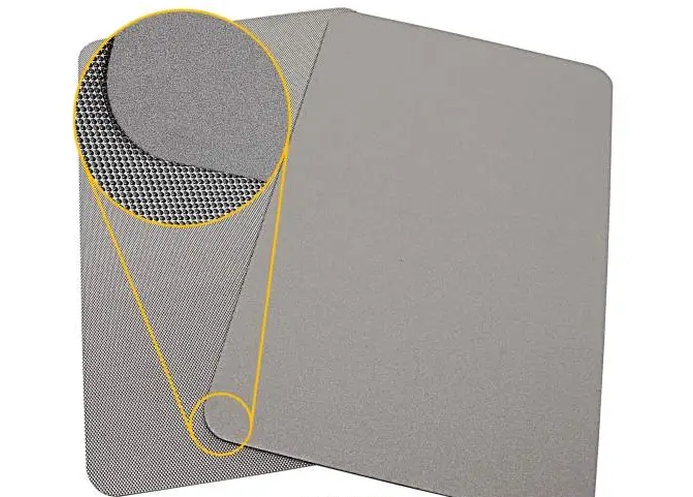

Utilizing powder metal technology, the HP-PTL has a highly porous structure comprised of a fine powder layer which increases surface area connectivity. This design also reduces electrical resistance, requiring a lower voltage to produce equal amounts of hydrogen, reducing energy consumption and improving the overall efficiency of electrolysis stacks.

The microstructure shows high Titanium surface in addition to a high porosity. This results in a further reduction of electrical and mass transport resistance leading directly to a system efficiency increase of up to 30% when compared to current metal sheet solutions on the market.

“Through the development of the HP-PTL, GKN Powder Metallurgy is driving the energy transition forward,” says Stefan Zeier, Senior VP Operations. “By reducing operational costs and enhancing the efficiency of PEM electrolysis, this innovation plays a crucial role in making renewable hydrogen production economically viable. As a result, it opens new possibilities for a safer, more cost-efficient future based on environmentally sustainable energy.”

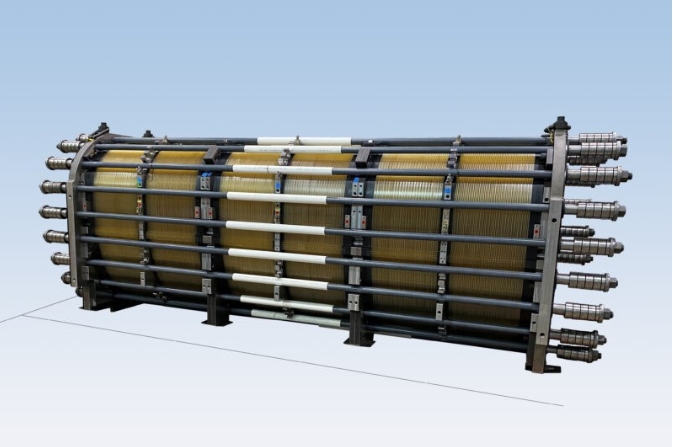

GKN Powder Metallurgy will be in attendance at the Hydrogen Technology Europe Expo taking place in Hamburg, Germany on 23rd and 24th October, where a model of the HP-PTL will be showcased in hall 2, stand B5.

About GKN Powder Metallurgy

GKN Powder Metallurgy is a world-leading provider of powder metal materials, components, and solutions. In co-development with its customers and business partners the company uses a unique range of best-in-class powder metallurgy technology to solve complex challenges in the automotive and industrial industries, delivering sustainable and innovative solutions.

GKN Powder Metallurgy is dedicated to achieving sustainable goals by providing leading powder metal expertise, innovative engineering, and extensive process experience to transform ideas into reality.

Part of the Dowlais Group plc, GKN Powder Metallurgy employs over 5,000 forward-thinking experts across 28 manufacturing locations and two innovation centers, ensuring the highest level of engineering excellence around the globe.

Source: FCW Team