Three-Circle (Group) Contributes to the Successful Commissioning of the 300 kW SOFC Demonstration Project at the East Campus of Shenzhen Guangming District People's Hospital

January 21, 2025, Shenzhen: The 300 kW Solid Oxide Fuel Cell (SOFC) demonstration project at the East Campus of Guangming People's Hospital, jointly constructed by Shenzhen Three-Circle (Group) and Shenzhen Gas Group Co., Ltd., was officially put into operation.

Panoramic View of the Project

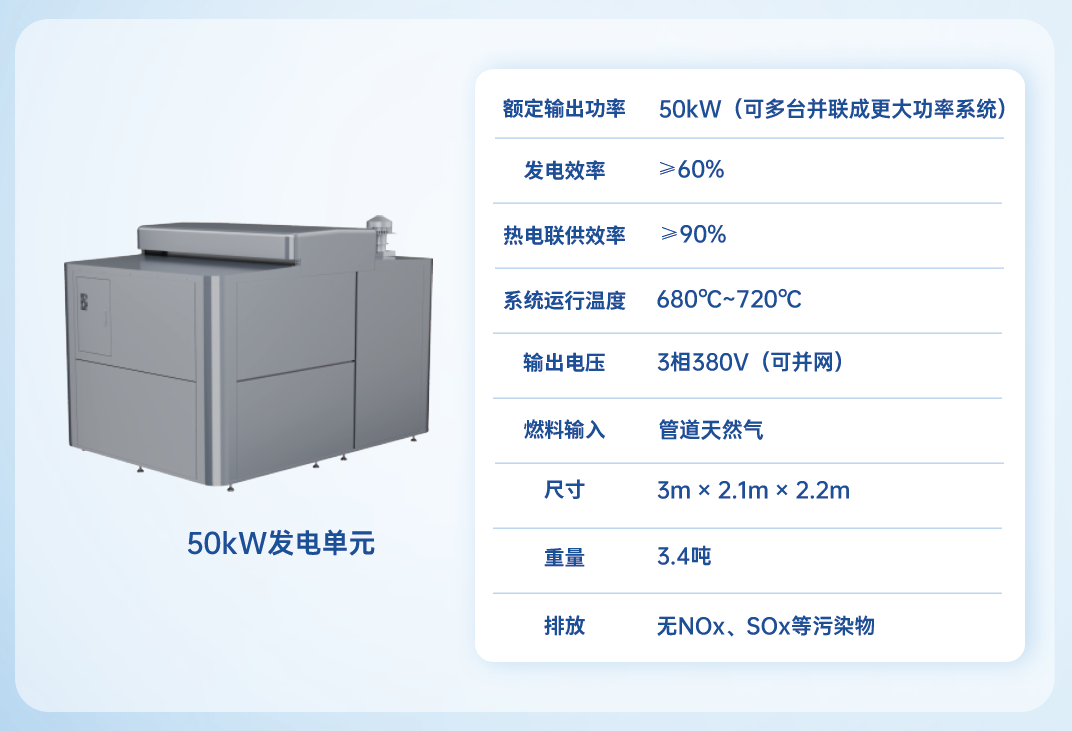

This project is the first 300 kW SOFC commercial promotion demonstration project in the country and the promotion and application of the "First Set of Major Equipment in the Energy Field" products issued by the National Energy Administration. The project is composed of 6 power generation units with a power output of 50 kW each, which can provide stable power for the hospital.

Image: Three-Circle (Group)

As of now, the total power generation during the trial operation of the project has reached 110,000 kW-hours, and the average power generation efficiency is as high as 64.4%, which is at the global advanced level. It is expected that the annual power generation can reach 2.3 million kW-hours, and the annual carbon reduction can reach approximately 320 tons.

The SOFC technology is an efficient and clean power generation technology that directly converts chemical energy into electrical energy through electrochemical reactions. It has the characteristics of high-power generation efficiency and strong fuel adaptability.

In 2024, SOFC technology was included in the "Green Technology Promotion Catalogue (2024 Edition)" issued by eight departments including the National Development and Reform Commission.

Since 2004, Three-Circle (Group) has been focusing on the innovation and integration of production and research in SOFC/SOEC, continuously overcoming various key challenges. After more than 20 years of continuous investment and technological research, Three-Circle (Group) has now become one of the core links in the global SOFC/SOEC industry chain. It has mastered the R&D and mass production capabilities of the entire SOFC/SOEC technology chain, from single cells, stacks to systems. It holds more than 50 core invention patents and took the lead in launching the first domestic 35kW and 50kW high-power SOFC power generation systems. It also takes the lead in undertaking the key R&D programs during the "13th Five-Year Plan" and "14th Five-Year Plan" periods and is committed to providing safe and reliable new energy technology alternatives for the efficient utilization of renewable energy in the process of achieving the "carbon peak and carbon neutrality" goals.

As a subsidiary of Three-Circle (Group), Shenzhen Three-Circle has a group of high-level technical personnel covering various professional fields such as materials, electrochemistry, machinery, and mechanics. It also has testing equipment for material analysis, electrochemical analysis, etc.

In the future, Shenzhen Three-Circle will continue to cooperate closely with the Guangming District Government, Shenzhen Gas Group Co., Ltd. and other units, actively respond to the national carbon peak and carbon neutrality strategies. Starting from the SOFC demonstration project in the People's Hospital, it will explore the promotion and application in more scenarios and contribute to the construction of Shenzhen as a green and low-carbon city.

Source: GuanmingNews