ディーゼル車と同等のパフォーマンス!? 米国の「水素エンジン」トラックは実用性を高める新たなフェーズに!

米国の非営利・独立研究機関、SwRIは大型トラック用に「水素燃焼エンジン」の実用化を目指すコンソーシアムの第2フェーズを立ち上げたことを発表した。エンジンメーカーなどがメンバーとなっているコンソーシアムは昨年、デモンストレーション車両として水素エンジンの大型トラックを完成させていた。

第2フェーズでは車両全体のパフォーマンスと効率をさらに向上し、水素エンジンが代替駆動技術を補完する実用的なソリューションとなることを目指している。 文/トラックマガジン「フルロード」編集部 写真/Courtesy of SwRI

SwRIの「水素エンジンコンソーシアム」は第2フェーズに

内燃エンジンの研究で長い歴史を持つ米国の非営利研究機関、サウスウェスト・リサーチ・インスティテュート(SwRI)は2025年3月25日、水素を燃料とする内燃エンジン(水素エンジン)のコンソーシアム「H2-ICE」の第2フェーズとなる「H2-ICE2」を立ち上げたと発表した。 SwRIのH2-ICEコンソーシアムは昨年、18カ月の開発期間(目標)を経て水素エンジンを搭載する大型トラック(北米の重量車区分で最も重い「クラス8」)を完成させている。このデモンストレーション車両はディーゼル車と比較して、性能を犠牲にすることなくCO2(二酸化炭素)及びNOx(窒素酸化物)の排出を大幅に低減した。 その成功を継承するH2-ICE2では、車両全体でのパフォーマンスと効率をさらに向上することを目指すという。 なおコンソーシアムのメンバーは、SwRIのほかカミンズ、ボッシュ、アリソン、イートン、キャタピラー、HD現代・インフラコア、エクソンモービル、シェルなど輸送業界のリーダーが集まっており、革新的な水素エンジン技術により持続可能なモビリティを前進させることを目指している。 コンソーシアムでは引き続き水素内燃機関を「他のゼロ排出車両技術を補完するもの」と位置づけ、バッテリーEVや燃料電池EVなど他の駆動技術を排除するのではく、それを補う技術としての可能性を証明する。 こうすることでエンジンメーカーやトラックメーカー、部品のサプライヤー、燃料・消耗品のプロバイダーに、「現実的な」脱炭素のロードマップを示す狙いがあり、SwRIのバイスプレジデントでパワートレーン開発部門を率いるダニエル・スチュワート氏は次のように話している。 「私たちは、内燃エンジンの開発では100年以上の歴史を持っていますが、トラックの製造において水素を燃料とする内燃機関はとりわけ魅力的なソリューションとなると考えています。世界中に存在しているメーカーの既存の製造ラインやコンポーネントの供給網をそのまま活用できるからです。水素エンジンは今すぐに実現可能な、実用的なゼロ排出ソリューションなのです」。

パフォーマンスを犠牲にしない脱炭素ソリューションを訴求

SwRIの水素エンジントラックは2024年に全米を巡航し、温室効果ガスを排出しない大型トラックにパフォーマンスを犠牲にすることなく実現可能な、もう一つの選択肢があることを長距離輸送業界に伝えた。 H2-ICE2では、今後2年間をかけてデモンストレーション車両を改良し、試験方法やシステムの強化を通じて全体としてのパフォーマンスと効率を改善する。 SwRIのパワートレーン開発部門のマネージャー、ライアン・ウィリアムズ氏によると、第1フェーズでは「水素を燃料とするエンジンの開発と、それによって可能になること」を示すのが目的だったが、第2フェーズではただのデモンストレーションではなく、実際のニーズに合った機能的で実用的な車両を目指すという。 コンソーシアムは2026年12月までの間、様々な現実世界の条件下で車両のパフォーマンス維持、熱管理、効率性の持続などについて研究を進めることにしている。また、車両のコールドスタート(冷間始動)、連続する上り坂、極低速走行や空荷状態の無負荷運転など、実際の商用トラックではよくある状況についても評価する予定だ。 SwRIはこうした試験やパフォーマンス改善のためにエンジン本体を新たに開発したり、ハードウェアを大幅に変更する必要はないと考えており、パワートレーンシステム開発部門のエドワード・M・スミスIII氏は次のように話している。 「このコンソーシアムはエンジン開発を目的としたものではなく、車両全体を対象としたものになります。(H2-ICEで試作した)既存の車両を活用することで水素エンジンの運用に特有の長所と短所を特定し、ソリューションを設計する予定です。 既に水素エンジントラックの調整・改善が可能な点をいくつか見つけています。例えば、トルク応答を改善する戦略や、排出量をさらに削減するための急速ウォームアップモードの導入などを検討しています。 コンソーシアムのメンバーの知識を結集することで開発を前進させ、技術的なハードルを克服し、2050年までにネットゼロを実現する道を切り開いていきます」。

ディーゼル車と同等のパフォーマンス!? 米国の「水素エンジン」トラックは実用性を高める新たなフェーズに!(ベストカーWeb) - Yahoo!ニュース

ディーゼル車と同等のパフォーマンス!? 米国の「水素エンジン」トラックは実用性を高める新

米国の非営利・独立研究機関、SwRIは大型トラック用に「水素燃焼エンジン」の実用化を目指すコンソーシアムの第2フェーズを立ち上げたことを発表した。エンジンメーカーなどがメンバ

news.yahoo.co.jp

'New Energy' 카테고리의 다른 글

| 수소경제 ‘주인공’ 그린수소 시장… 중국에 잠식 우려 (0) | 2025.04.10 |

|---|---|

| Electric Hydrogen HYPRPlant cuts electrolysis plant costs by 60% (2) | 2025.04.09 |

| 「自動車産業のノウハウが生きた」ボッシュが水素製造で全力 (0) | 2025.04.04 |

| 汇客厅|大全集团执行总裁葛飞:成立人才攻关联合体,在绿电制氢产业化上寻求突 (0) | 2025.04.03 |

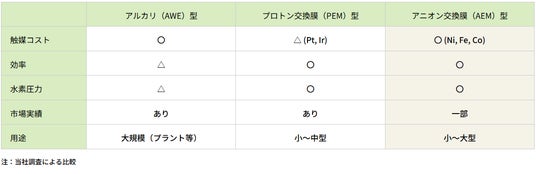

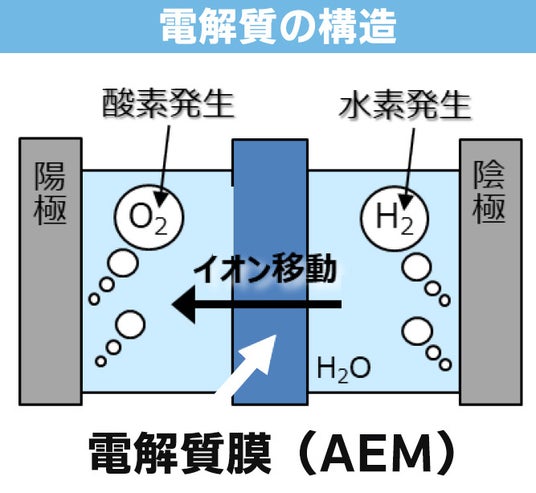

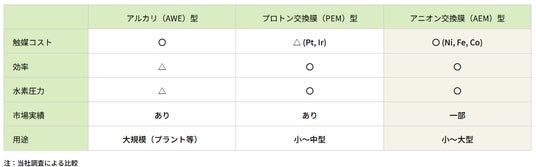

| 水素製造機能膜量産準備プロジェクトチームの発足について (0) | 2025.04.03 |