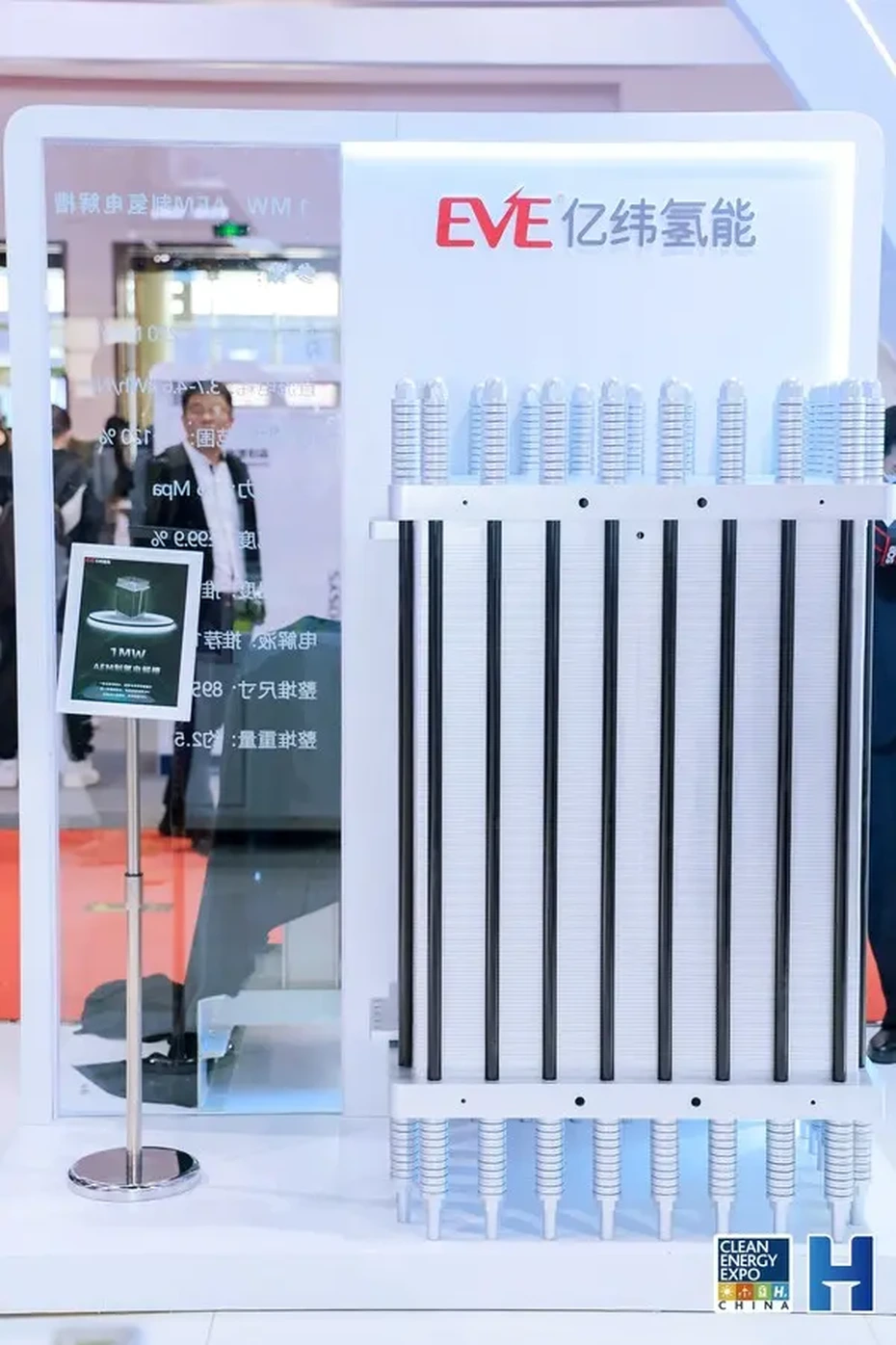

EVE Hydrogen Energy Showcases MW-Level Hydrogen Energy Storage Multi-Scenario Solutions at the 4Th China International Hydrogen Energy Exhibition (CHEE)

BEIJING-- On March 26, EVE Hydrogen Energy unveiled its 1MW AEM Electrolyzer at the 4th China International Hydrogen Energy Exhibition in Beijing, marking China's entry into the global hydrogen technology elite. Aligned with the theme "Breaking Boundaries, Empowering Scenarios," the innovation accelerates green hydrogen autonomy and highlights policy-driven progress.

Technological Breakthroughs Redefine Industry Standards

Responding to carbon neutrality goals and China's 14th Five-Year Plan, EVE Hydrogen Energy's electrolyzer redefines benchmarks through three breakthroughs:

- Integrated Flow Field Design: Achieves 75-80% LHV efficiency and 60,000+ hours lifespan.

- Advanced Electrodes: Enables 5.0 A/cm² power density via 20% current density boost.

- Compact Stack: Reduces footprint by 30% for large-scale projects.

With a 230 Nm³/h output at 4.6–4.8 kWh/Nm³, it breaks single-stack power limits. Proprietary non-precious catalysts and ion-conductive membranes cut costs by 40% versus PEM methods, while achieving 95% localization. Operating at 1.4 MPa with 15-minute cold starts, it supports volatile renewables and high-pressure industrial needs.

Scenario Revolution: Full Ecosystem Solutions for Diverse Needs

EVE Hydrogen Energy showcased MW-level Hydrogen Storage Solutions, integrating AEM electrolyzers with PV and energy storage (backed by EVE Lithium Energy, the world's No.2 energy storage cell supplier). Key features:

- Dynamic Power Matching: Raises renewable utilization by 35%.

- Peak-Valley Arbitrage: Creates a closed-loop "produce-store-apply" system.

As a leader in AEM localization, EVE Hydrogen Energy has overcome material and integration bottlenecks, establishing full-chain R&D capabilities. It now accelerates deployment in industrial decarbonization and green metallurgy, aiming to reduce green hydrogen costs and support China's 2030 targets. By fostering global partnerships, the company is reshaping hydrogen competition—one breakthrough at a time.

EVE Hydrogen Energy Showcases MW-Level Hydrogen Energy