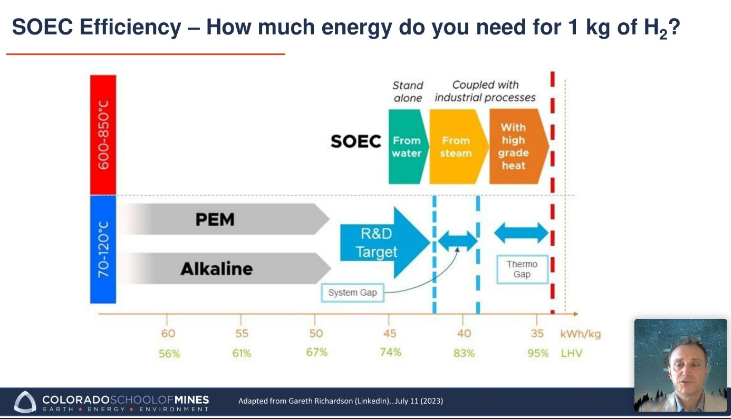

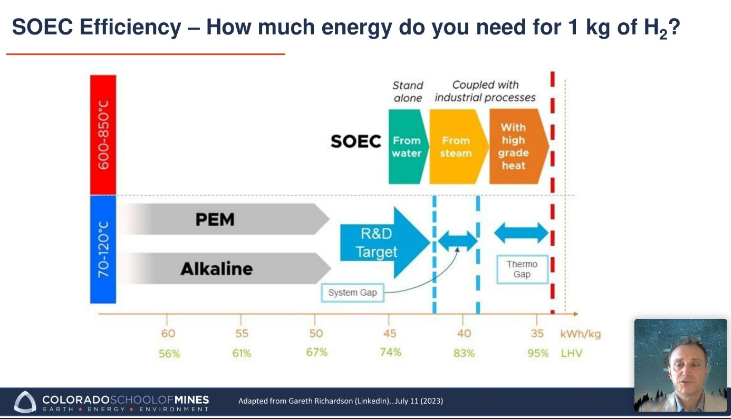

SOEC efficiency & R&D Target

スウェーデンのSSABは27日、水素還元製鉄技術開発のハイブリットの成果を確認し、実装段階に入ると発表した。2016年の開発開始以降、成果を上げており、パイロット設備で生産した「化石燃料フリー」の鋼材の供給も開始している。6年間の研究成果を最終報告書にまとめており、今後スウェーデン政府に報告する。天然ガスによる還元よりも優れた特性も確認できたとしており、電炉による効率的な溶解技術など成果を上げ、複数の特許も取得したという。

| Uniper opens new storage facility for green hydrogen in Krummhörn (0) | 2024.09.02 |

|---|---|

| SOEC efficiency & R&D Target (0) | 2024.08.30 |

| World’s first-of-its-kind green ammonia plant inaugurated in Denmark (0) | 2024.08.30 |

| HYBRIT: Six years of research paves way for industrial-scale fossil-free iron and steel production (0) | 2024.08.30 |

| Air Liquide inaugurates 20MW electrolyser in Oberhausen (0) | 2024.08.30 |

Topsoe, Skovgaard Energy, and Vestas have inaugurated a new green ammonia plant in Ramme, Denmark. The plant will produce 5,000 tons of green ammonia annually from renewable electricity, preventing 8,200 tons of CO₂ from being emitted into the atmosphere every year.

The plant will demonstrate a dynamic approach by adapting to the inherent fluctuations in power output from renewable sources, integrating with the plant’s electrolysis and ammonia synthesis loop. This will ensure optimal production and improve cost-effectiveness. With power sourced from renewables, the produced ammonia will be labelled as green ammonia. 10 MW of electrolyser capacity was supplied by Nel Hydrogen.

Ammonia – whether as low-carbon ammonia or an e-fuel – is expected to play a critical role in the world’s journey towards net zero. It can be transported using existing infrastructure and has multiple end uses, including as a fuel, a hydrogen carrier, and in decarbonising industrial processes like steel and cement production.

Kim Hedegaard, CEO Power-to-X at Topsoe, said: “With this new facility, we are taking an important step, which will benefit both Denmark and the rest of the world. We need to continue the development of green alternatives for energy-intensive industries and long-distance transportation with research, innovation and action. This project is a unique example of going from good intentions to actively supporting the energy transition.”

Niels Erik Madsen, CEO at Skovgaard Energy, said: “We have achieved a milestone in Denmark. Until today, we have been able to supply plenty of green power to the power grid, but we have not been able to store it or convert it to the needs of industry. We are now able to do just that, when we turn green electricity into green ammonia.”

Source: Hydrogentechworld

The HYBRIT initiative has presented six years of research results in a final report to the Swedish Energy Agency. The report shows that direct reduced iron produced with the HYBRIT process has superior characteristics compared to iron produced with fossil fuels.

HYBRIT has applied for and received several patents based on these successful results. The project is now moving into the next phase, where the process will be implemented on an industrial scale.

The HYBRIT initiative is a collaboration between the steel company SSAB, the mining company LKAB, and the energy company Vattenfall, launched to fundamentally transform the iron and steel industry. The initiative aims to virtually eliminate carbon dioxide emissions in the steel industry by replacing coal and coke in the production of iron with fossil-free hydrogen and electricity. The transition from coal and blast furnace-based steelmaking to HYBRIT technology, along with the melting of iron in electric arc furnaces, is expected to reduce Sweden’s total carbon dioxide emissions by more than 10%.

The project is the first in the world to demonstrate that a fossil-free value chain – from iron ore to steel – can work on a semi-industrial scale. To date, more than 5,000 tonnes of hydrogen-reduced iron have been produced at HYBRIT’s pilot plant in Luleå. Customers such as Volvo Group, Epiroc, Peab, and others are already using fossil-free steel in vehicles, heavy machinery, buildings, and consumer products, with strong interest in the technology continuing to grow.

Martin Pei, Chief Technology Officer at SSAB and Chairman of the Board of Hybrit Development AB, commented: “I am incredibly proud of everything HYBRIT has achieved since its launch in 2016. Thanks to the successful results of the pilot project, we are well on our way to fundamentally changing the iron and steel industry. At SSAB, we are now investing heavily to convert the entire Nordic production system to fossil-free steel production and have already started delivering fossil-free steel to customers on a smaller scale.”

The research results, now presented in a final report to the Swedish Energy Agency, cover the period from 2018 to 2024. They focus on scaling up technical solutions from the laboratory to industrial scale, developing an industrial process practice and achieving an integrated value chain for hydrogen-based iron and steelmaking.

Key results from the pilot phase include the development of a new hydrogen-based technology for efficient, fossil-free iron and steel production with 0.0 tonnes of CO₂ emissions per tonne of steel. Additionally, a new fossil-free iron product (sponge iron) was developed, boasting significantly better properties than iron reduced with fossil gases like natural gas. The project also achieved the successful long-term operation of alkaline electrolysers for hydrogen production and storage, and the development of an efficient process for melting fossil-free sponge iron into crude steel in an electric arc furnace.

“The focus of HYBRIT’s technical development has been to build up expertise and create technical conditions for the implementation of a fossil-free process in a full-scale production,” said Ulf Spolander, General Manager of Hybrit Development AB. “We are very pleased that we as a team have been able to deliver successful results that have met or exceeded the set project goals. The knowledge and experience we have developed during the project will now be focused on continuing the process development, primarily to support the owners´ industrialisation projects.”

The results from the pilot phase pave the way for implementing the HYBRIT process on an industrial scale. Hybrit Development AB will continue research and development to support the industrialisation of the technology together with the owner companies, including delivering solutions to LKAB’s planned demonstration plant in Gällivare. The pilot project for storing fossil-free hydrogen in Svartöberget in Luleå, will continue until 2026.

“It has been a groundbreaking journey in a short period of time,” said Jenny Greberg, Vice President Technology at LKAB and board member of Hybrit Development AB. “The results from the pilot phase show that the process works and that we are ready for the next stage, where the demonstration plant that LKAB plans to build in Gällivare will be the first step towards industrial production of sponge iron. Our high-quality iron ore combined with good access to fossil-free energy provides unique conditions for establishing a competitive value chain for future fossil-free iron and steel production.”

The HYBRIT project has received funding from the EU Innovation Fund and Industriklivet. It is also part of the European IPCEI project Hy2Use (Hydrogen), which involves a total of 35 projects from 12 countries to support rapid transition and increase the competitiveness of the European industrial sector.

Source: Hydrogentechworld

On 26 August, Air Liquide inaugurated its 20MW electrolyser at its Oberhausen site in Germany. The plant is connected to Air Liquide’s existing hydrogen pipeline, allowing it to supply key industries and zero-emission mobility in the Rhine and Ruhr area with up to 2,900 tons of green hydrogen annually.

Named ‘Trailblazer’, the 20MW PEM electrolyser is the largest production plant for renewable hydrogen in Germany connected to existing infrastructure. The facility makes a significant contribution to the energy transition and serves as a backbone for key industries such as steel, chemicals, and refinery, as well as for mobility. The electrolyser stacks were manufactured at the Air Liquide-Siemens Energy joint venture gigafactory in Berlin.

Gilles Le Van, Chairman of the Supervisory Board of Air Liquide Deutschland GmbH: “We are very pleased to be able to celebrate a milestone in the industrial transformation in the heart of the Ruhr area with today’s inauguration of the electrolyser. The integration into an existing hydrogen infrastructure will accelerate the decarbonisation of key industries in North Rhine-Westphalia and promote low-carbon mobility in this densely populated region. This shows what can be achieved if the authorities and companies are working towards a common goal.”

Hendrik Wüst, Prime Minister of North Rhine-Westphalia, added: “Hydrogen is a key to a climate-neutral future, especially in energy-intensive industries such as steel and chemicals in North Rhine-Westphalia. The commissioning of the Trailblazer electrolyser is an important signal for our industrial location and a milestone for climate protection in North Rhine-Westphalia. As the state government, we support and accompany the development of a robust and innovative hydrogen economy through targeted measures. It is a crucial prerequisite for us to become the first climate-neutral industrial region in Europe.”

Source: Hydrogentechworld